PES Projects

Practical Engineered Solutions

Mobile Lithium Extraction Plant Assembly

- Design and engineering of Direct Lithium Extraction (DLE) Process

- Design and engineering of entire DLE processing plant

- Project Management of entire project

- Procurement

- Construction

- Testing

- Installation

- Took project from design to construction

- Manage operations of DLE Process facility

Oil Reclamation Facility

- Engineering of entire facility

- Procurement of all equipment

- Process equipment design manufacturing

- Project management of construction

- Oversight and management of installation, construction, and facility operations

.jpeg)

Oil and Gas Production Facility

- Engineering of entire facility

- Procurement of all equipment

- Process equipment manufacturing

- Project management of construction

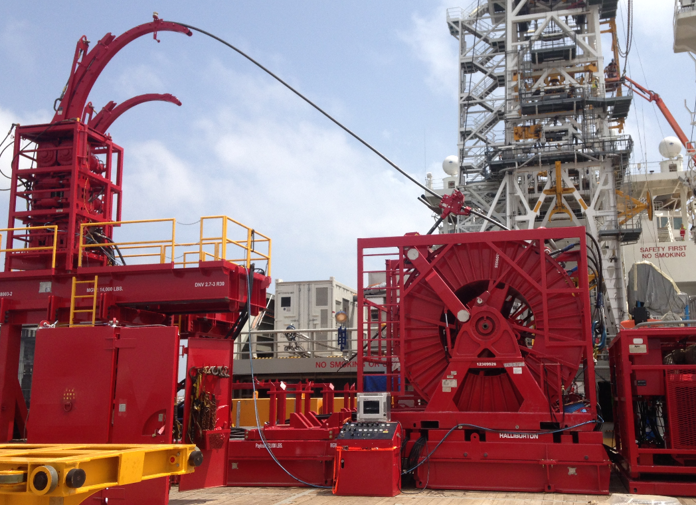

Coil Tubing Deployment Skid

Frac Stack Pack Specification

- 150K Coil tubing deployment skid design, engineering, procurement and construction

- Took project from napkin sketch all the way through construction

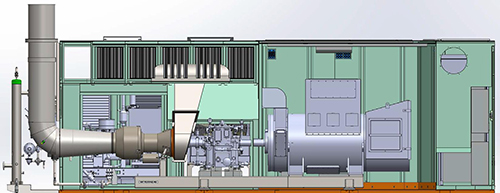

TURBINE POWERED FRAC UNITS

Frac Stack Pack Specification

- Engine: T-55 or TF-40 Turbine Engine

- Power: 3,850 HP

- Hydraulic Horsepower: 2,000 – 3,000 HHP

- Rate: Up to 48 BPM

- Pressure: Up to 20,000 PSI

- Emissions: Tier IV Compliant. 80% Less NOx and CO than Diesel Engines.

- Liquid Fuel: Runs on #2 Diesel and Bio-Fuel up to B-100

- Natural Gas: Runs on Field Gas, Pipeline Gas, CNG and LNG

- Transport: Frac Packs are Air Transportable

Multi-Skid Water Treatment Package

- 100 gallon per minute – Produced water treatment system

- Electro-chlorination system

- Compressible media filtration

- $5 million

1 MW POWER GENERATION PACKAGE

PERFORMANCE

- Output Power: 1,000kW – 480V

- Heat Rate: 13,200 BTU/kWe-hr

- Exhaust Flow: 11.7 lb/sec

- Exhaust Temperature: 1,100 Degrees F

- Nominal Rating – per ISO at 59 Degrees F, Sea Level

- No Inlet/Exhaust/Accessory Losses

- Relative Humidity 60%

- Natural Gas Fuel with LHV = ~1000 BTU/scf

Upgraded Saturation Diving System

- Upgraded 15-man saturation diving system with a three-man bell along with a new 165’ surface diving system

- $10.5 million upgrade of its Gulf of Mexico-based dive support vessel (DSV) Swordfish

- Dual 70 and 150 Te active heave compensated (AHC) cranes

- New build 18-man self-propelled hyperbaric lifeboat (SPHL)

- Newly built and dedicated portable hyperbaric rescue facility (HRF)

Food Manufacturing Projects

Boudin Facility Optimization

- Process optimization of Boudin facility to include custom equipment production

- $2 million

Enrichment and Custom Nutrient Production Facility

- Using chillers for ethanol recovery and production processes

- Production process improvement

- Custom production equipment

- Production equipment design improvements

- $1.5 million

"It has been a complete pleasure working with the PES staff. Their responsiveness and commitment to hitting their promised deliveries are second to none."

"PES have provided our company with unparalleled customer service and top quality work on many successful projects. We continue to use PES for our engineering requirements because of their rapid response, professionalism, accuracy and attention to detail. Every PES employee we have worked with has been a consummate professional and eager to contribute to the success of our projects and company."

"Practical Engineering Solutions has been a great pleasure to deal with for our company. The demand for high volumes of process equipment to be delivered to our customers on time is constant and we cannot afford to wait on any part of our projects. PES has stepped up to the plate at any given time with any information needed. PES has also assisted us greatly with newly designed products for our company with efficiency, organization, and great skill."

"PES has consistently come through for our company on countless successful products. One project that we have completed for a customer with PES was awarded as the Spotlight on New Technology award at OTC 2014. PES's team offers top notch services, around the clock response, and expert advice whenever needed. I would definitely recommend PES to anyone that asks."

ASME Pressure Vessel Capabilities

ASME Vessel Design, Engineering & Code Compliance

Civil / Structural Engineering Capabilities:

- Structural strength / FEA analysis of onshore and offshore structures (API 4F)

- Tool design and FEA strength analysis

- Foundation engineering and design

- Structural engineering

- Commercial buildings and Structures

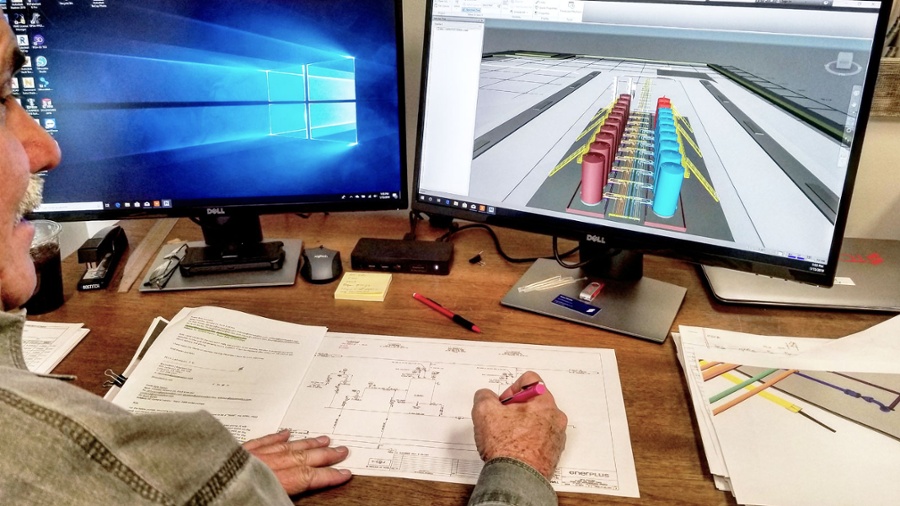

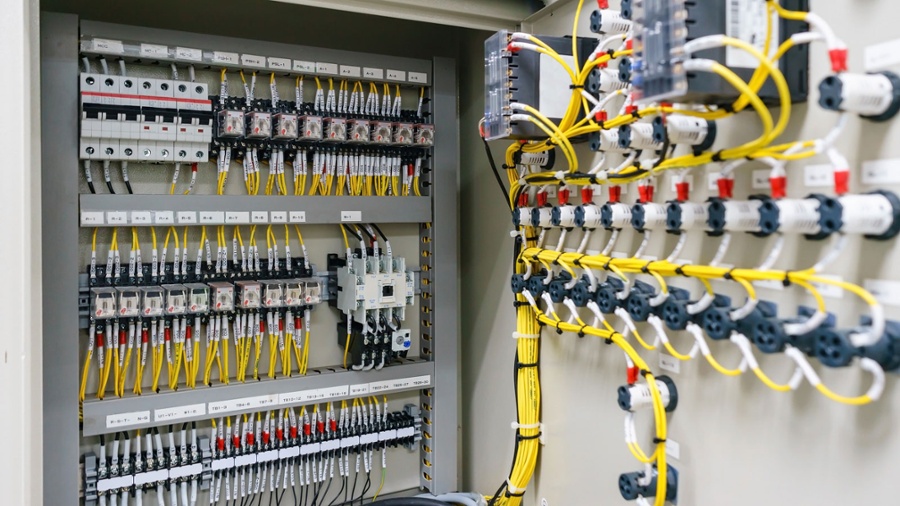

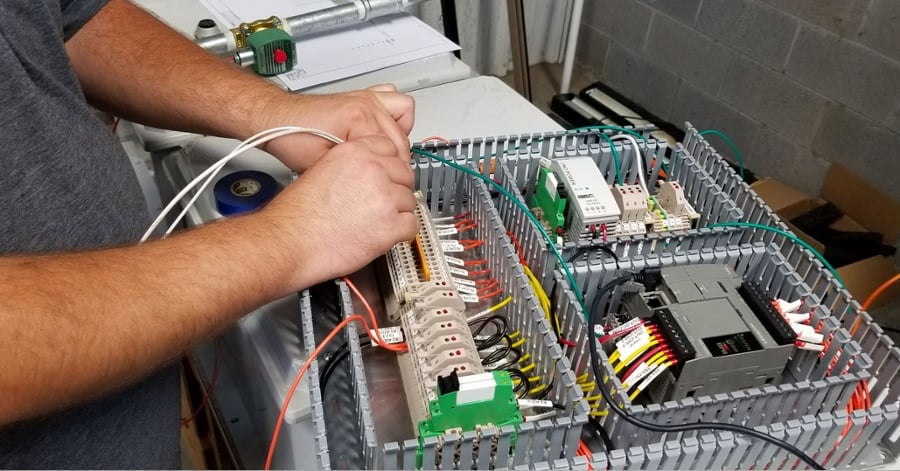

Electrical Engineering / Automation Capabilities

- Electrical design and engineering

- Electrical Panel and breaker design

- PLC automation design

Piping / Pipeline System Capabilities

-

ASME B31.3, B31.4, B31.7, B31.8 piping system design & engineering

-

Line sizing per API for flow rates

-

Compressor stations / pipeline design and engineering

Coiled Tubing & Well Servicing Equipment Capabilities

API 4F / 8C well servicing equipment design and code compliance

Wellhead & Surface Tree Equipment

API 6A / ASME VIII, Div 2 High Pressure Analysis & Compliance

Oil & Gas Facility Designs

- Oil & Gas process equipment design

- Separators, line heaters, treaters, glycol dehydration, amine units, flare systems, etc.

Direct Lithium Extraction Facilities

- Direct lithium extraction process design

- Extraction from concentrated brine solutions

Downhole Tool Equipment Capabilities:

- API Specification 11D1 Packers and Bridge Plugs

- Hydraulic/Mechanical Whipstock System Design: Cased and Openhole

- Hydraulic Whipstock Packer Anchor Design

- Wireline Setting Tool Design

- Dissolvable Frac-Plug Design

- Casing Scraper and BOP Jetting Tool design

- Negative Pressure Test Packer

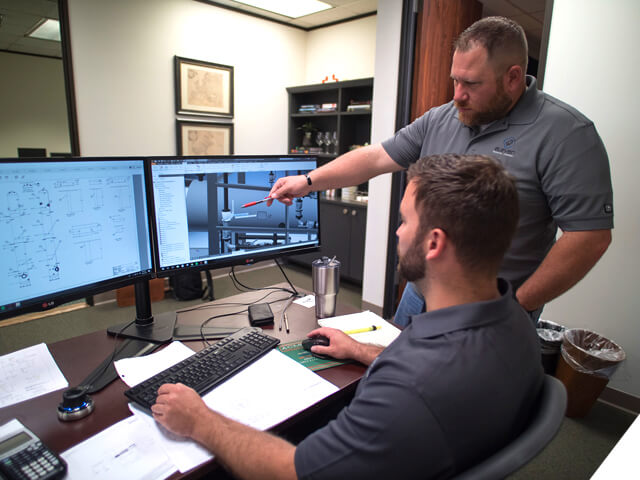

Project Management Services

On-site project management services for all aspects of construction

Inspection Services

Team of over 250 inspectors to inspect and manage project quality (CWI, API, ASME, etc.)

Startup & Commissioning Services

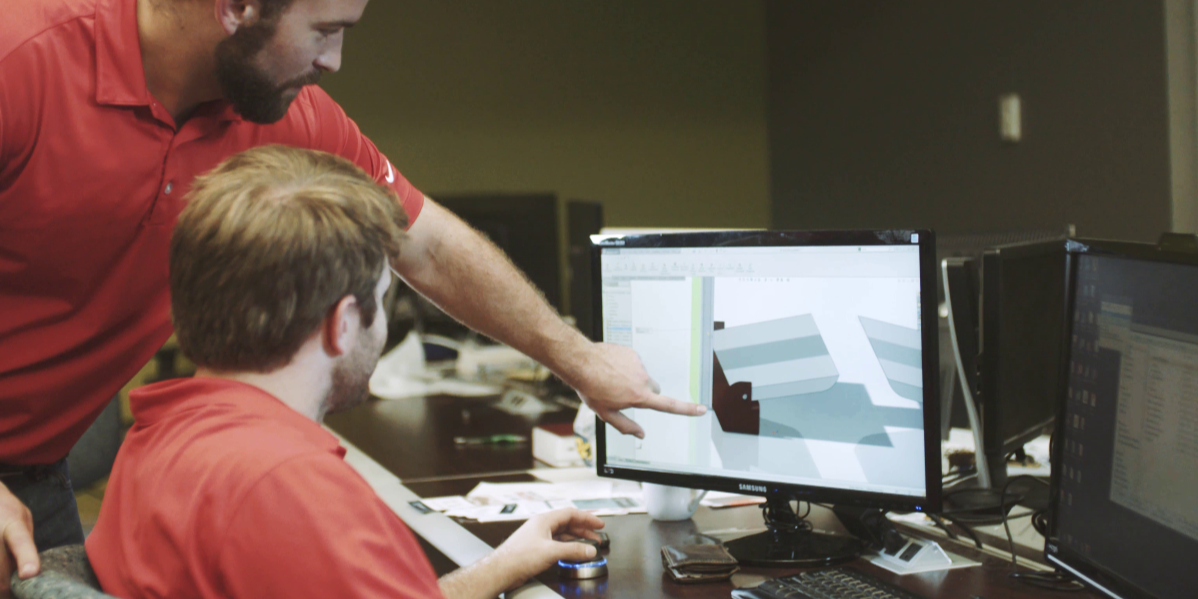

FEED Study Capabilities

PES can provide complete FEED (Front End Engineering & Design) studies to tell you what kind of process equipment you need. We have the software capacities to run complete heat and mass balance simulations based on the specific flow stream conditions you may have.

We can run bottleneck analysis to show you where the “weak-links” are in your process equipment as well as optimization studies to increase productivity. We can provide this over single satellite installations or an entire gathering network with interconnecting pipelines.

List of Capabilities:

- FEED Studies – Sizing all of your process equipment based on your well specific properties. We are provided with flow rates (oil, water, gas, sand, etc.) and we specify all of the process equipment they need to separate and sell it.

- Heat & Mass Balance Simulations / Process Simulations – Full chemical breakdown of all process flow medium to specify the proper equipment to handle these flows.

- Bottleneck Analysis – Determines where the “weak-link” in the process equipment chain is. What component in the process equipment train is limiting the flow of oil, water or gas. What component(s) is governing the max flow in the system. Wells change the amount of oil, water and gas they produce over time. So what once was a good equipment train, may now not be suited for the new flow rates. Typically as wells get older they produce less natural gas and more oil and water.

- Optimization Studies – Similar to bottleneck in that it optimizes the equipment design. PES specifies the optimum size of process equipment they need to process oil, water and gas.

- Degassing / Flare System Design – Size / simulate degassing and flare systems to burn off excess waste gas that they cannot get to sales.

- Gas Dehydration or Sweetening – Simulations to dry gas through glycol dehydration to remove water from gas or Amine sweeting (for sour gas) to remove sour gas in the form of H2S.

Do you get our newsletter?

Don’t be left out - sign up to receive the latest insights and news delivered straight to your inbox.